Unleashing Complexity: Why Ceramic Injection Molding Excels for Intricate Parts

When engineers dream up geometries full of twists, voids, rib networks, and internal channels, they often worry whether any manufacturing method can bring those plans to life. But Ceramic Injection Molding (CIM) is one of the few processes that can routinely turn those geometrical fantasies into functional reality while ensuring stable performance in extreme operating conditions. Below are five compelling reasons why CIM is especially suited for parts with complex geometries.

1. Design Freedom for Truly Intricate Shapes

Before we dive deeper, imagine shapes so elaborate that conventional methods just can’t make them without extensive secondary work. CIM often handles those elegantly.

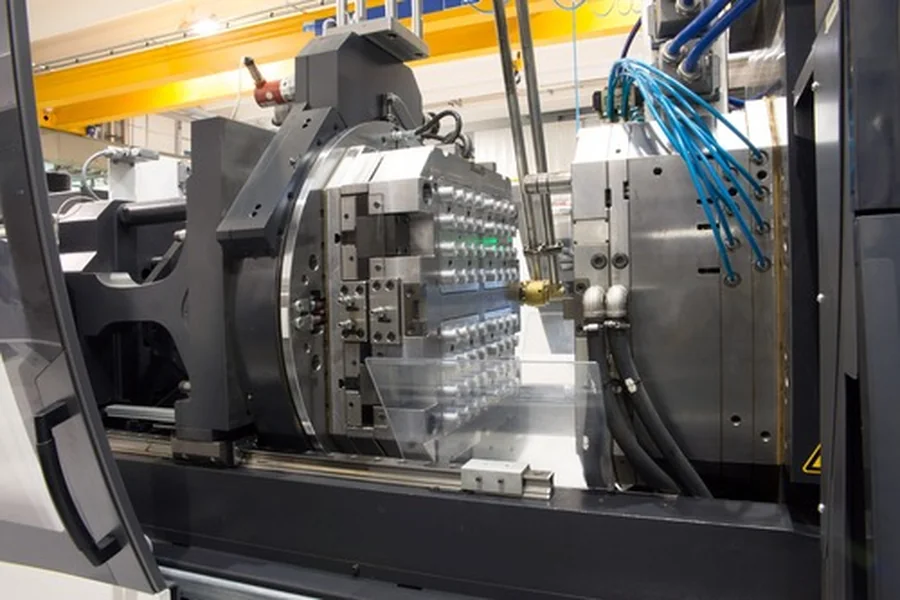

One of the most transformative advantages of CIM is its ability to mold internal cavities, undercuts, thin walls, lattice structures, and fine detailing all in one shot. Traditional ceramic techniques like pressing or slip casting struggle with such complexity, often requiring machining or assembly to finish the part. CIM, by contrast, blends the precision of injection molding with the desirable properties of ceramics to produce parts with features that would otherwise be impractical or prohibitively costly.

This capacity to deliver elaborate designs encourages innovation: components such as sensor housings, microfluidic channels, and even complex dental implants are increasingly realized with CIM, where every nook and cranny matters.

2. Near-Net Shape Production Reduces Finishing Steps

When your part comes out of the mold already close to its final shape, that’s a big win.

CIM is often classified as a near-net or net-shape process. That means the molded part emerges very close to its target geometry and dimensional tolerances, which reduces the need for costly and time-consuming post-machining.

Because much of the geometry is “built in,” delicate features remain intact. That’s especially critical when secondary machining may damage or distort fragile walls or internal channels. In short: fewer finishing steps, less waste, and better yield.

3. Tight Tolerances and Excellent Detail Resolution

If your design demands exacting tolerances or very small features, CIM has what it takes.

CIM routinely delivers parts with fine detail and tight tolerance control. Reports mention wall thicknesses as small as 0.2 mm and feature sizes down to 0.1 mm in some cases.

This level of precision is possible because the feedstock (ceramic powder + binder) enters the mold under high pressure and conforms well to the mold cavity. The mold itself is built with high-precision machining to capture fine detail. As long as designers account for shrinkage during sintering, the repeated part-to-part consistency is excellent.

That said, challenges do exist, features may shift slightly during the debinding and sintering phases, and cores or inserts may be needed to support deep cavities. But with robust design and tooling, CIM handles what many alternate methods cannot.

4. Material Performance Meets Complex Geometry

You don’t lose performance by going complex – CIM delivers functional materials in those intricate shapes.

When you combine ceramic materials (such as alumina or zirconia) with injection molding techniques, you get parts that carry the advantages of advanced ceramics – high hardness, wear resistance, thermal stability, chemical resistance, while also supporting complex form.

In applications where space, weight, or functionality demand tailored geometry (for example, cooling channels in a compact engine, sensor housings with integrated seals, or surgical tools with unusual profiles), CIM allows you to exploit ceramic performance in ways that forging, machining, or simpler molding can’t.

You’re not just getting complexity for complexity’s sake, you’re getting a high-performance component that’s more efficient, compact, and tailored to function.

5. Scalability, Consistency & Cost Efficiency for Complex Parts

A process may be great for one prototype but useless for volume. CIM is suited for both prototyping and production.

Once the tooling is in place, CIM enables consistent, repeatable production of complex parts. The per-unit cost falls sharply as volume increases. Because most of the shape is taken care of by the mold, there’s minimal machining waste or labor.

Moreover, excess or leftover feedstock (binder + powder) can often be recycled, reducing waste.

In many cases, the material cost savings, lower finishing burden, and high consistency make CIM more economical, especially when your geometry would otherwise force multiple assemblies, joins, or high-waste machining from solid stock.

Fun fact: Some CIM parts incorporate internal cooling channels or microfluidic pathways impossible to machine or assemble by hand, these are akin to organic systems embedded within ceramics.

Also, in one advanced technique, engineers can combine additive manufacturing and CIM to make tooling or cores for shapes that even conventional molds can’t reach. This hybrid approach is pushing the boundary of what “complex” means.

For parts demanding both geometry and performance, Ceramic Injection Molding stands out as one of the few manufacturing routes that doesn’t force you to compromise. Its ability to deliver intricate shapes, near-net geometry, tight tolerances, and ceramic-level properties, and do so at scale, makes it ideal for fields like aerospace, healthcare, electronics, and advanced sensors.

If you’re designing a part with internal passages, overhangs, lattices, or any complicated internal geometry, CIM deserves a spot in your shortlist of candidate processes.

Post Comment

You must be logged in to post a comment.